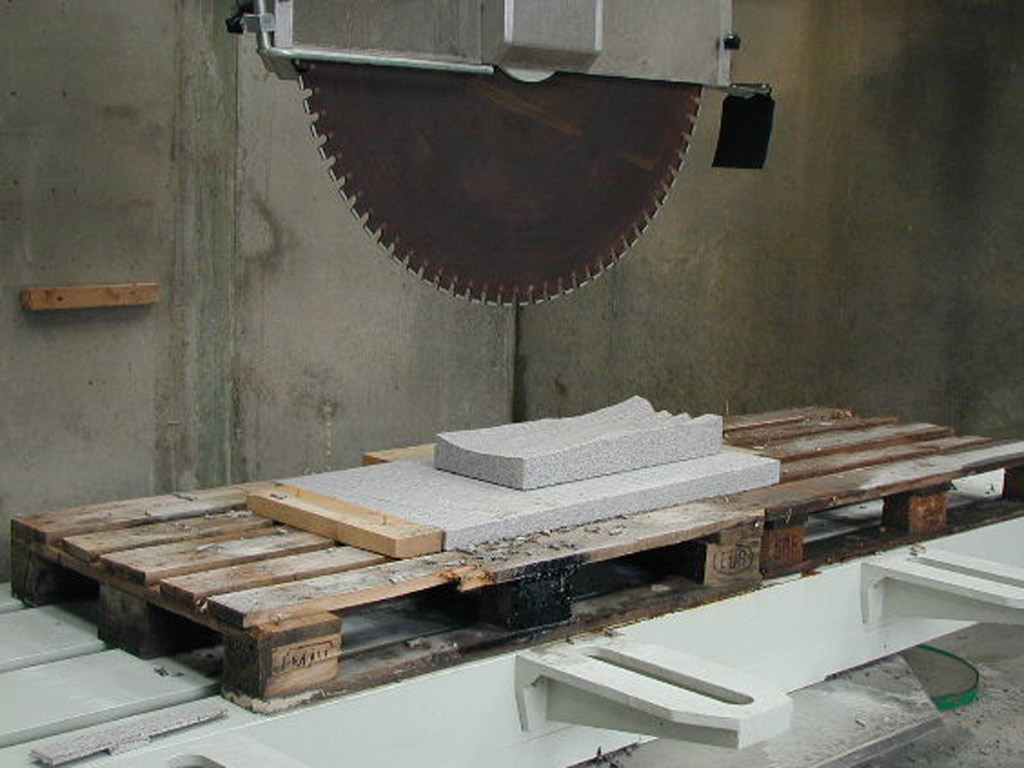

- Machine suitable for both small and large workshops for marble / granite.

- Bridge main frame / table in cast iron for stability / minimum vibration/greater machine life.

- Long-lasting stainless steel protective covering.

- Small-dimension motor connected directly to blade, with inverter.

- Blade unit / bridge action electronically controlled on bearings, by encoder.

- Head vertical action with auto-braking motor, controlled by encoder on prismatic guide.

- Motorised rotating bench with auto-positioning 0° – 360°; blocking with hydraulic brakes.

- 0° – 90° tilting head even for small runs, auto-blockable in position with hydraulical brake.

- P 55 LX cabinet houses electronic and electrical control / right-left slide, forward-backward bridge movement, head rising / lowering, bench rotation.

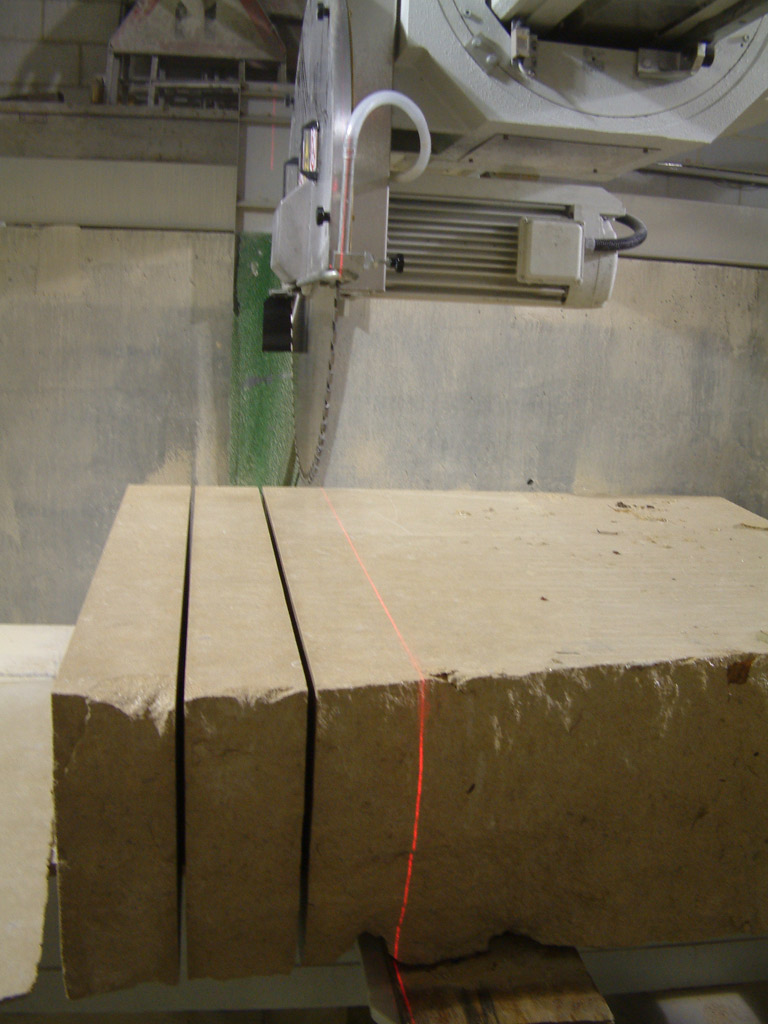

- Collimatore a raggio laser per facilitare il posizionamento del disco sulla linea di taglio.

- Laser beam for ease of positioning of blade on cutting line.

Bridge main frame / table in cast iron for stability / minimum vibration/greater machine life.

- Automatic axes control with fast reaction; translation of bridge; automatic table rotation.

- Electronic tilting of blade cutting unit.

- Single marble run / small increasing granite steps according to programmed depth.

- Selection of 20 different cutting widths to be repeated up to 99 times.

- Cutting, and blade head return limit switches self-setting electronically.

- Beam movement limit switches self-setting.

- Differential regulation of cut-and-return speed and last cut speed.

- Automatic bench tilt programming for continuous circular or orthogonal cutting.

- Through runs or part runs possible.

- All axes can be moved together to reduce lime wastage.

- Profiles can be set directly from keyboard; concave / convex arches on rising/descending tilts of any angle.

- Linear and circular profiles for horizontal / vertical axes of the blade head possible.

- Resident menu cycles: cross-cutting, facing – slab-cutting, concave-convex, shaping, interpolated shaping.

- Specific prog. with CAD/CAM, converter and ISO, for profiles and shapes drawn on CAD connected externally in serial RS 232 (optional)